Algorithm_Longitudinal

This module is responsible for the control of the vehicle’s longitudinal behavior. It receives the command variables from a driver behavior model and generates the accelerator and brake pedal position and the current gear of the driver to match these command variables. The pedal positions and the gear can then be forwarded to a vehicle dynamics module like Dynamics_RegularDriving. The actuation of the clutch pedal is currently not simulated by the modul

Detailed description of the module’s features

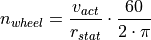

Inverted longitudinal dynamics model

The inverted longitudinal dynamics model produces  by utilizing an inverted powertrain and brake system model. The powertrain model

and all of its parameters and state variables are illustrated in the following image.

The brake model is not worth illustrating, as it directly applies on the required acceleration

by utilizing an inverted powertrain and brake system model. The powertrain model

and all of its parameters and state variables are illustrated in the following image.

The brake model is not worth illustrating, as it directly applies on the required acceleration

of the vehicle.

of the vehicle.

Illustration of the powertrain model and its parameters and state variables

The core element of all calculations in this model is speed and acceleration.

The speed  at the wheels is constraint by the current velocity

at the wheels is constraint by the current velocity

of the vehicle and the static wheel radius

of the vehicle and the static wheel radius  :

:

where  is specified in

is specified in  (revolutions per minute) and

(revolutions per minute) and  is

defined in

is

defined in  , which requires the conversion term at the end of the equation.

As the equation also illustrates, only a simple rolling relation defines the

model and there is no simulation of tire-road-friction and tire slip involved.

, which requires the conversion term at the end of the equation.

As the equation also illustrates, only a simple rolling relation defines the

model and there is no simulation of tire-road-friction and tire slip involved.

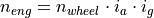

The speed  of the engine is constraint by the speed

of the engine is constraint by the speed

of the wheels, the ratio

of the wheels, the ratio  of the axle, and the

current ratio

of the axle, and the

current ratio  of the gearbox, depending of the current gear:

of the gearbox, depending of the current gear:

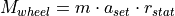

The required acceleration  determines the torque

determines the torque  at the wheels, as the overall mass

at the wheels, as the overall mass  of the vehicle has to be accelerated by

this torque:

of the vehicle has to be accelerated by

this torque:

As the equation illustrates, no driving resistances other than the inertia of

the vehicle are simulated by this model. The required torque  at the wheels must be generated by the engine, considering the ratios of the

powertrain:

at the wheels must be generated by the engine, considering the ratios of the

powertrain:

As the current speed  of the engine, the required acceleration

of the engine, the required acceleration

of the vehicle, and the required torque

of the vehicle, and the required torque  of the

engine are known or defined by the above equations, this knowledge can be used

to determine the estimated positions of the accelerator and the brake pedal or

to calculate the optimal gear for the required acceleration

of the

engine are known or defined by the above equations, this knowledge can be used

to determine the estimated positions of the accelerator and the brake pedal or

to calculate the optimal gear for the required acceleration  ,

if a positive acceleration is needed. For the accelerator pedal and optimal gear

calculation, there is still some missing knowledge about the engine itself.

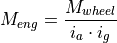

The relationship between the current engine speed

,

if a positive acceleration is needed. For the accelerator pedal and optimal gear

calculation, there is still some missing knowledge about the engine itself.

The relationship between the current engine speed  and the

possible engine torque

and the

possible engine torque  is determined by a simple engine map,

which is illustrated in the following image:

is determined by a simple engine map,

which is illustrated in the following image:

Simplified engine map used for the inverted powertrain model

The engine map is defined by two characteristic curves:

defines the maximum torque, which can be produced by the

engine at a specific engine speed

defines the maximum torque, which can be produced by the

engine at a specific engine speed  . This is directly connected

with the maximum possible actuation of the accelerator pedal.

. This is directly connected

with the maximum possible actuation of the accelerator pedal. defines the drag torque, which is produced by the engine

at a specific engine speed

defines the drag torque, which is produced by the engine

at a specific engine speed  , if the accelerator pedal is not

actuated at all.

, if the accelerator pedal is not

actuated at all.

The two characteristic curves are only defined between the minimum and maximum

possible speed of the engine. As the two characteristic curves are directly

related to a full actuation ( ) and no actuation

(

) and no actuation

( ) of the accelerator pedal, the estimated pedal

position for the accelerator pedal

) of the accelerator pedal, the estimated pedal

position for the accelerator pedal  , which produces the

currently required engine torque

, which produces the

currently required engine torque  , can be calculated by linear

interpolation between these two characteristic curves at the current engine

speed

, can be calculated by linear

interpolation between these two characteristic curves at the current engine

speed  .

.

Analogous for the brake pedal position:

The maximum actuation of the brake pedal (

) is

directly connected with the maximum possible deceleration of the vehicle, which

is simply set to 1G (

) is

directly connected with the maximum possible deceleration of the vehicle, which

is simply set to 1G ( ).

).No actuation of the brake pedal (

) also produces no

deceleration.

) also produces no

deceleration.

Between these two possible decelerations, the estimated brake pedal position to

produce the required acceleration  is calculated by linear

interpolation.

is calculated by linear

interpolation.

The logic for the calculation of the static controller output  ,

utilizing the considerations above, is defined as follows:

,

utilizing the considerations above, is defined as follows:

If the required acceleration  is smaller than zero, it can be

produced by the engine drag torque or the brake system. If the engine drag

torque

is smaller than zero, it can be

produced by the engine drag torque or the brake system. If the engine drag

torque  at the current engine speed

at the current engine speed  is not

strong enough to meet the engine torque

is not

strong enough to meet the engine torque  , which would be

necessary to produce

, which would be

necessary to produce  , an additional actuation of the brake

pedal is applied (the driver does not open the clutch, so the engine drag torque

is also applied to the wheels). This mechanism is not considering a change in

gears, but uses the current gear of the gearbox (the driver does not consider to

shift down for a stronger effect of the engine drag torque).

, an additional actuation of the brake

pedal is applied (the driver does not open the clutch, so the engine drag torque

is also applied to the wheels). This mechanism is not considering a change in

gears, but uses the current gear of the gearbox (the driver does not consider to

shift down for a stronger effect of the engine drag torque).

If the required acceleration  is greater than or equal to zero,

it can only be produced by the powertrain. First of all, the optimal gear to

produce the engine torque

is greater than or equal to zero,

it can only be produced by the powertrain. First of all, the optimal gear to

produce the engine torque  required for

required for  is

calculated, which is described in the subsequent subsection.

With this chosen gear, the current engine speed

is

calculated, which is described in the subsequent subsection.

With this chosen gear, the current engine speed  is calculated.

is calculated.

is used to determine the maximum engine torque

is used to determine the maximum engine torque  and the engine drag torque

and the engine drag torque  from the characteristic curves.

As these two values are connected to a full actuation and no actuation of the

accelerator pedal, the estimated accelerator pedal position, which is necessary

to produce the required acceleration

from the characteristic curves.

As these two values are connected to a full actuation and no actuation of the

accelerator pedal, the estimated accelerator pedal position, which is necessary

to produce the required acceleration  , can be calculated by

linear interpolation.

, can be calculated by

linear interpolation.

The state variable  is received from the module Sensor_Driver,

the required acceleration

is received from the module Sensor_Driver,

the required acceleration  is received from a driver behavior

model, and the vehicle parameters

is received from a driver behavior

model, and the vehicle parameters  ,

,  ,

,  ,

,  per gear,

and the information about the engine map are received from the module Parameters_Vehicle.

per gear,

and the information about the engine map are received from the module Parameters_Vehicle.

The calculations above are done in the function CalculatePedalPositions, which is called in the function CalculatePedalPositionAndGear of Algorithm_Longitudinal.

Algorithm for optimal gear determination

The algorithm for the determination of the optimal gear for the required

acceleration  is implemented in the function CalculateGearAndEngineSpeed.

It is called within the function CalculatePedalPositionAndGear of Algorithm_Longitudinal,

which applies the inverted longitudinal dynamics model.

The algorithm receives the current velocity

is implemented in the function CalculateGearAndEngineSpeed.

It is called within the function CalculatePedalPositionAndGear of Algorithm_Longitudinal,

which applies the inverted longitudinal dynamics model.

The algorithm receives the current velocity  of the vehicle and the required acceleration

of the vehicle and the required acceleration  .

.

Within a for-loop over all gears, the engine speed  is calculated

for each gear, which would result from the current velocity

is calculated

for each gear, which would result from the current velocity  ,

as well as the maximum engine torque

,

as well as the maximum engine torque  and the engine drag

torque

and the engine drag

torque  resulting from these engine speeds. Violating the

minimum engine speed

resulting from these engine speeds. Violating the

minimum engine speed  and the maximum engine speed

and the maximum engine speed  is not considered in this step (resulting engine speeds are written as they result

from the powertrain calculation and the engine torques are set to the lower or

upper limits of the characteristic curves respectively, if the engine speed

range is violated).

is not considered in this step (resulting engine speeds are written as they result

from the powertrain calculation and the engine torques are set to the lower or

upper limits of the characteristic curves respectively, if the engine speed

range is violated).

The results above are further processed in a second for-loop over all gears. The following aspects are checked to determine, if a gear fits the current required state:

Is the resulting engine speed

within the range of

within the range of  and

and  ?

?Is the resulting engine torque

to produce the required

acceleration

to produce the required

acceleration  within the range of

within the range of  and

and  ?

?

The lowest gear that fits these criteria sets a Boolean foundGear true and the

results (gear number and resulting engine speed  ) are written in

the result vector. This is done for all further gears, until a gear does not fit

the requirements anymore. This initiates the return of the last sufficient gear

and its resulting engine speed

) are written in

the result vector. This is done for all further gears, until a gear does not fit

the requirements anymore. This initiates the return of the last sufficient gear

and its resulting engine speed  . A short example should

illustrate this logic:

. A short example should

illustrate this logic:

The 2nd gear activates the Boolean foundGear, because

does

not exceed

does

not exceed  anymore

anymoreThe 4th gear activates the return of the results, because the required engine torque

would exceed the maximum possible engine torque

would exceed the maximum possible engine torque  at the corresponding engine speed

at the corresponding engine speed

The algorithm chooses the 3rd gear as optimum and returns it and its corresponding engine speed

This logic therefore guarantees, that always the highest possible gear is chosen by the driver.