AlgorithmLongitudinalDriver

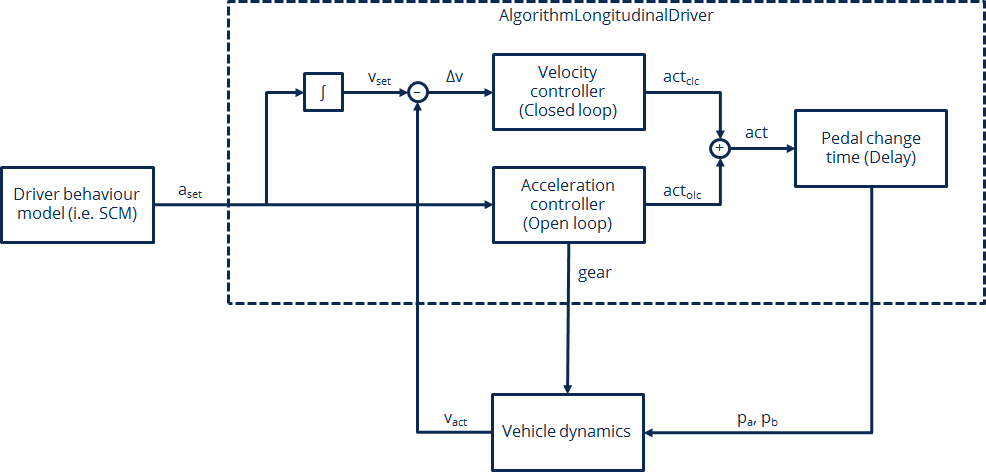

This module is responsible for the control of the vehicle’s longitudinal dynamics. It receives the command variables from a driver behaviour model like Implementation Architecture and generates the accelerator and brake pedal position and the current gear of the driver to match these command variables. The pedal positions and the gear have than to be send to a vehicle dynamics module like DynamicsRegularDriving. The actuation of the clutch pedal is currently not simulated by the module.

Overview of the module’s functionalities

AlgorithmLongitudinalDriver models human longitudinal guidance according to the two-level-model of vehicle guidance from Donges. It is the original form of his later three-level-model of vehicle guidance, which is expressing driver behaviour in a more phenomenological context, and was developed as part of Donges’ Ph.D. thesis (Donges only focussed on lateral guidance in this work, which is the base for the algorithms in AlgorithmLateralDriver; the phenomenology behind this model is transferred to longitudinal guidance in AlgorithmLongitudinalDriver). The model takes two overlapping mechanisms of human behaviour in human-machine-interactions into account:

Anticipatory open-loop control on guidance level: Every driver has knowledge about how his vehicle works, which is based on driving experience and familiarity with the vehicle. This can be expressed as a mental model representation about the vehicle. If the driver formulates a desired acceleration, he can use his knowledge about the vehicle to estimate, how much he has to press the accelerator pedal, so the vehicle’s powertrain generates the desired acceleration. This is a typically open-loop control process, where the mental representation of the vehicle represents a feedforward control, which generates a pedal position according to a desired acceleration, but the actual acceleration, which is produced by the vehicle, is not monitored. The better the mental model of the vehicle is, the better is this feedforward control, but even the best mental model cannot take into account external disturbances like slope. For influences like this, a second underlying control mechanism is needed.

Compensatory closed-loop control on stabilization level: As already mentioned above, the guidance level cannot take into account any external disturbance, because an open-loop control does not monitor the difference between command variable and its corresponding system state. For this reason (and to compensate the driver’s necessarily imperfect mental model about his vehicle), an underlying closed-loop control is needed. For instance, a driver is driving at his target speed on a plane road, which means that the required acceleration to reach his target speed is equal zero. In this case, the guidance level will also produce an accelerator pedal position equal to zero engine torque (compensation of powertrain drag can be part of the anticipatory open-loop control, if the driver’s mental model is sophisticated enough). If an external disturbance like a slope occurs, the state of the anticipatory level will not change, because this kind of driving resistance cannot be addressed by a feedforward control. The vehicle will of cause start to decelerate and therefore deviate from the target speed of the driver, which must be compensated by a closed-loop control that monitors the actual velocity of the vehicle.

Contrary to lateral guidance (AlgorithmLateralDriver), longitudinal guidance of a passenger car requires the actuation of two pedals, namely accelerator and brake pedal. As these two are furthermore controlled with the same foot, there is a necessary pedal change time when switching between pedals, which is modelled as a stochastic delay in the module’s signal chain.

AlgorithmLongitudinalDriver is currently modelled for the control of vehicles with manual transmissions, which incorporates an algorithm for the selection of the optimal gear. The actuation of a clutch pedal is not simulated by the module.

Detailed description of the module’s features

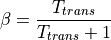

AlgorithmLongitudinalDriver receives its command variables from a driver behaviour model like Implementation Architecture and generates the pedal positions and the gear of the driver to match these command variables. The pedal positions of all controllers are summed up to the overall pedal position of the driver, which is complemented by a maybe necessary pedal change time and is than send to a vehicle dynamics module like DynamicsRegularDriving. The pedal positions within the module’s algorithms are defined as double values between -1 and 1, where values between 0 and 1 indicate accelerator actuation and values below 0 indicate brake pedal actuation. This is split up into two seperate output signals for accelerator and brake pedal by the function UpdateOutputParameters, but it makes handling inside the algorithms much easier. The gear is calculated within the inverted vehicle model of the open-loop controller. The control loop is closed by the movement of the vehicle. This overall control loop of vehicle longitudinal guidance involving AlgorithmLongitudinalDriver is illustrated in Fig. 52 with the following variables:

is the desired acceleration of the vehicle

is the desired acceleration of the vehicle is the desired velocity of the vehicle, which is

is the desired velocity of the vehicle, which is  integrated over time

integrated over time is the actual velocity of the vehicle

is the actual velocity of the vehicle is the velocity error

is the velocity error is the pedal position signal from the acceleration controller

is the pedal position signal from the acceleration controller is the pedal position signal from the velocity controller

is the pedal position signal from the velocity controller is the overall pedal position of the controllers

is the overall pedal position of the controllers is the output signal for the accelerator pedal position

is the output signal for the accelerator pedal position is the output signal for the brake pedal position

is the output signal for the brake pedal position is the current gear of the driver

is the current gear of the driver

Fig. 52 Components and signal flow of the longitudinal guidance control loop

The following subsections describe the theoretical background and the transfer functions of the different controllers.

Anticipatory control on guidance level

As described in the overview section,

the driver’s controls on guidance level are characterized by anticipatory

mechanisms regarding the expected vehicle’s behaviour. In terms of control

theory and longitudinal guidance, this is modelled as an open-loop feedforward

controller, which generates an estimated pedal position  that

fits a required acceleration

that

fits a required acceleration  from the driver behaviour model.

This model-predictive controller is modelled as an inverted longitudinal

dynamics model of the vehicle’s powertrain and brake system. In terms of control

theory, this is a complex proportional controller, which is further complemented

by a first order transient behaviour. Therefore, the whole anticipatory

open-loop controller can be interpreted as a

from the driver behaviour model.

This model-predictive controller is modelled as an inverted longitudinal

dynamics model of the vehicle’s powertrain and brake system. In terms of control

theory, this is a complex proportional controller, which is further complemented

by a first order transient behaviour. Therefore, the whole anticipatory

open-loop controller can be interpreted as a  unit. The inverted

longitudinal dynamics model also includes an algorithm for the selection of the

optimal gear, regarding the required torque on the wheels to generate

unit. The inverted

longitudinal dynamics model also includes an algorithm for the selection of the

optimal gear, regarding the required torque on the wheels to generate  . The several aspects of this model are described below.

. The several aspects of this model are described below.

Inverted longitudinal dynamics model

The inverted longitudinal dynamics model produces the proportional part  of the open-loop acceleration controller by utilizing an inverted powertrain and

brake system model (see here for the application of the transient behaviour to calculate

of the open-loop acceleration controller by utilizing an inverted powertrain and

brake system model (see here for the application of the transient behaviour to calculate  from

from  ). The powertrain model and all of its parameters and

state variables are illustrated in Fig. 53. The brake model is not worth

illustrating, as it directly applies on the required acceleration

). The powertrain model and all of its parameters and

state variables are illustrated in Fig. 53. The brake model is not worth

illustrating, as it directly applies on the required acceleration  of the vehicle.

of the vehicle.

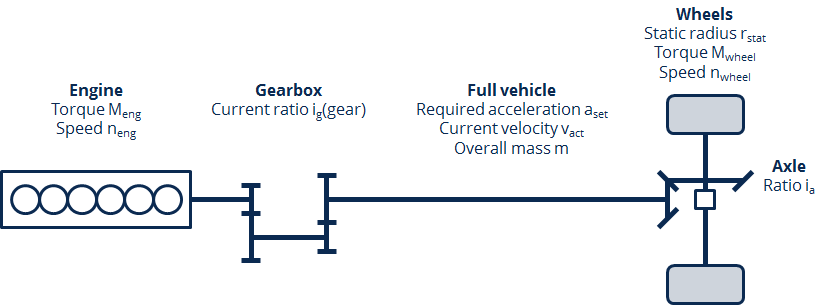

Fig. 53 Illustration of the powertrain model and its parameters and state variables

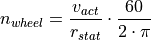

The core element of all calculations in this model is speed and acceleration.

The speed  at the wheels is constraint by the current velocity

at the wheels is constraint by the current velocity

of the vehicle and the static wheel radius

of the vehicle and the static wheel radius  :

:

where  is defined in rotations/min and

is defined in rotations/min and  is

defined in m/s, which requires the conversion term at the end of the equation.

As the equation also illustrates, only a simple rolling relation defines the

model and there is no simulation of tire-road-friction and tire slip involved.

is

defined in m/s, which requires the conversion term at the end of the equation.

As the equation also illustrates, only a simple rolling relation defines the

model and there is no simulation of tire-road-friction and tire slip involved.

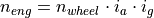

The speed  of the engine is constraint by the speed

of the engine is constraint by the speed

of the wheels, the ratio

of the wheels, the ratio  of the axle, and the

current ratio

of the axle, and the

current ratio  of the gearbox, depending of the current gear:

of the gearbox, depending of the current gear:

The required acceleration  determines the torque

determines the torque  at the wheels, as the overall mass

at the wheels, as the overall mass  of the vehicle has to be accelerated by

this torque:

of the vehicle has to be accelerated by

this torque:

As the equation illustrates, no driving resistances other than the inertia of

the vehicle are simulated by this model. The required torque  at the wheels must be generated by the engine, considering the ratios of the

powertrain:

at the wheels must be generated by the engine, considering the ratios of the

powertrain:

As the current speed  of the engine, the required acceleration

of the engine, the required acceleration

of the vehicle, and the required torque

of the vehicle, and the required torque  of the

engine are known or defined by the above equations, this knowledge can be used

to determine the estimated positions of the accelerator and the brake pedal or

to calculate the optimal gear for the required acceleration

of the

engine are known or defined by the above equations, this knowledge can be used

to determine the estimated positions of the accelerator and the brake pedal or

to calculate the optimal gear for the required acceleration  ,

if a positive acceleration is needed. For the accelerator pedal and optimal gear

calculation, there is still some missing knowledge about the engine itself.

The relationship between the current engine speed

,

if a positive acceleration is needed. For the accelerator pedal and optimal gear

calculation, there is still some missing knowledge about the engine itself.

The relationship between the current engine speed  and the

possible engine torque

and the

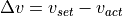

possible engine torque  is determined by a simple engine map,

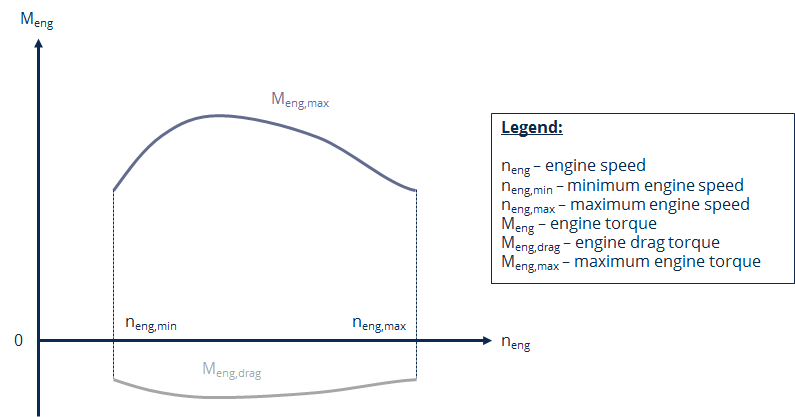

which is illustrated in Fig. 54:

is determined by a simple engine map,

which is illustrated in Fig. 54:

Fig. 54 Simplified engine map used for the inverted powertrain model

The engine map is defined by two characteristic curves:

defines the maximum torque, which can be produced by the

engine at a specific engine speed

defines the maximum torque, which can be produced by the

engine at a specific engine speed  . This is directly connected

with the maximum possible actuation of the accelerator pedal.

. This is directly connected

with the maximum possible actuation of the accelerator pedal. defines the drag torque, which is produced by the engine

at a specific engine speed

defines the drag torque, which is produced by the engine

at a specific engine speed  , if the accelerator pedal is not

actuated at all.

, if the accelerator pedal is not

actuated at all.

The two characteristic curves are only defined between the minimum and maximum

possible speed of the engine. As the two characteristic curves are directly

related to a full actuation ( ) and no actuation

(

) and no actuation

( ) of the accelerator pedal, the estimated pedal

position for the accelerator pedal

) of the accelerator pedal, the estimated pedal

position for the accelerator pedal  , which produces the

currently required engine torque

, which produces the

currently required engine torque  , can be calculated by linear

interpolation between these two characteristic curves at the current engine

speed

, can be calculated by linear

interpolation between these two characteristic curves at the current engine

speed  .

.

The same thing is done for the calculation of the estimated brake pedal position:

The maximum acuation of the brake pedal (

) is

directly connected with the maximum possible deceleration of the vehicle, which

is simply set to 1G (

) is

directly connected with the maximum possible deceleration of the vehicle, which

is simply set to 1G ( ).

).No actuation of the brake pedal (

) also produces no

deceleration.

) also produces no

deceleration.

Between these two possible decelerations, the estimated brake pedal position to

produce the required acceleration  is calculated by linear

interpolation.

is calculated by linear

interpolation.

The logic for the calculation of the static controller output  ,

utilizing the considerations above, is defined as follows:

,

utilizing the considerations above, is defined as follows:

If the required acceleration  is smaller than zero, it can be

produced by the engine drag torque or the brake system. If the engine drag

torque

is smaller than zero, it can be

produced by the engine drag torque or the brake system. If the engine drag

torque  at the current engine speed

at the current engine speed  is not

strong enough to meet the engine torque

is not

strong enough to meet the engine torque  , which would be

necessary to produce

, which would be

necessary to produce  , an additional actuation of the brake

pedal is applied (the driver does not open the clutch, so the engine drag torque

is also applied to the wheels). This mechanism is not considering a change in

gears, but uses the current gear of the gearbox (the driver does not consider to

shift down for a stronger effect of the engine drag torque).

, an additional actuation of the brake

pedal is applied (the driver does not open the clutch, so the engine drag torque

is also applied to the wheels). This mechanism is not considering a change in

gears, but uses the current gear of the gearbox (the driver does not consider to

shift down for a stronger effect of the engine drag torque).

If the required acceleration  is greater than or equal to zero,

it can only be produced by the powertrain. First of all, the optimal gear to

produce the engine torque

is greater than or equal to zero,

it can only be produced by the powertrain. First of all, the optimal gear to

produce the engine torque  required for

required for  is

calculated, which is described in the subsequent subsection.

With this chosen gear, the current engine speed

is

calculated, which is described in the subsequent subsection.

With this chosen gear, the current engine speed  is calculated.

is calculated.

is used to determine the maximum engine torque

is used to determine the maximum engine torque  and the engine drag torque

and the engine drag torque  from the characteristic curves.

As these two values are connected to a full actuation and no actuation of the

accelerator pedal, the estimated accelerator pedal position, which is necessary

to produce the required acceleration

from the characteristic curves.

As these two values are connected to a full actuation and no actuation of the

accelerator pedal, the estimated accelerator pedal position, which is necessary

to produce the required acceleration  , can be calculated by

linear interpolation.

, can be calculated by

linear interpolation.

The state variable  is received from the module SensorDriver,

the required acceleration

is received from the module SensorDriver,

the required acceleration  is received from a driver behaviour

model like Implementation Architecture , and the

vehicle parameters m,

is received from a driver behaviour

model like Implementation Architecture , and the

vehicle parameters m,  ,

,  per gear,

and the information about the engine map are received from the module ParametersAgent.

per gear,

and the information about the engine map are received from the module ParametersAgent.

The calculations above are done in the function PedalPosition of the sub-module ALongitudinalDataProvider, which is called in the function CalculatePedalPositionAndGear of AlgorithmLongitudinalDriver.

Algorithm for optimal gear determination

The algorithm for the determination of the optimal gear for the required

acceleration  is implemented in the function GetBestGear of the

sub-module ALongitudinalDataProvider. It is called within the function

PedalPosition of the same sub-module, which applies the inverted longitudinal dynamics model

for the open-loop acceleration controller. The algorithm receives the current

velocity

is implemented in the function GetBestGear of the

sub-module ALongitudinalDataProvider. It is called within the function

PedalPosition of the same sub-module, which applies the inverted longitudinal dynamics model

for the open-loop acceleration controller. The algorithm receives the current

velocity  of the vehicle and the required acceleration

of the vehicle and the required acceleration  .

.

Within a for-loop over all gears, the engine speed  is calculated

for each gear, which would result from the current velocity

is calculated

for each gear, which would result from the current velocity  ,

as well as the maximum engine torque

,

as well as the maximum engine torque  and the engine drag

torque

and the engine drag

torque  resulting from these engine speeds. Violating the

minimum engine speed

resulting from these engine speeds. Violating the

minimum engine speed  and the maximum engine speed

and the maximum engine speed  is not considered in this step (resulting engine speeds are written as they result

from the powertrain calculation and the engine torques are set to the lower or

upper limits of the characteristic curves respectively, if the engine speed

range is violated).

is not considered in this step (resulting engine speeds are written as they result

from the powertrain calculation and the engine torques are set to the lower or

upper limits of the characteristic curves respectively, if the engine speed

range is violated).

The results above are further processed in a second for-loop over all gears. The following aspects are checked to determine, if a gear fits the current required state:

Is the resulting engine speed

within the range of

within the range of  and

and  ?

?Is the resulting engine torque

to produce the required

acceleration

to produce the required

acceleration  within the range of

within the range of  and

and  ?

?

The lowest gear that fits these criterions sets a Boolean foundGear true and the

results (gear number and resulting engine speed  ) are written in

the result vector. This is done for all further gears, until a gear does not fit

the requirements anymore. This initiates the return of the last sufficient gear

and its resulting engine speed

) are written in

the result vector. This is done for all further gears, until a gear does not fit

the requirements anymore. This initiates the return of the last sufficient gear

and its resulting engine speed  . A short example should

illustrate this logic:

. A short example should

illustrate this logic:

The 2nd gear activates the Boolean foundGear, because

does

not exceed

does

not exceed  anymore

anymoreThe 4th gear activates the return of the results, because the required engine torque

would exceed the maximum possible engine torque

would exceed the maximum possible engine torque  at the corresponding engine speed

at the corresponding engine speed

The algorithm chooses the 3rd gear as optimum and returns it and its corresponding engine speed

This logic therefore guarantees, that always the highest possible gear is chosen by the driver.

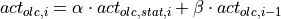

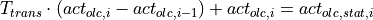

Transient behaviour application

The application of the transient behaviour is modelled as a discrete first order

controller with an amplification equal one. The input signal is the static pedal

position  from the inverted longitudinal dynamics model

and the output signal is the real pedal position

from the inverted longitudinal dynamics model

and the output signal is the real pedal position  of the

open-loop acceleration controller. A discrete first order controller calculates

the value of the output signal for the current time step

of the

open-loop acceleration controller. A discrete first order controller calculates

the value of the output signal for the current time step  , depending on the

current value of the input signal and the value of the output signal from the

last time step

, depending on the

current value of the input signal and the value of the output signal from the

last time step  by using two factors

by using two factors  and

and  .

Its transfer function is described as:

.

Its transfer function is described as:

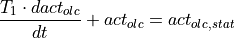

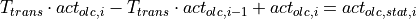

The more common form of a first order controller is the continuous transfer

function, including a time constant  and the time derivative

and the time derivative

of the output signal (amplification is also neglected):

of the output signal (amplification is also neglected):

expresses, how long the output signal needs to exceed 63 % of the

input signal. The change

expresses, how long the output signal needs to exceed 63 % of the

input signal. The change  of the output signal can also be

written in a discrete form and the change dt of time can be interpreted as the

step size of the discrete simulation. The ratio of the step size towards the

time constant

of the output signal can also be

written in a discrete form and the change dt of time can be interpreted as the

step size of the discrete simulation. The ratio of the step size towards the

time constant  is furthermore substituted with

is furthermore substituted with  ,

which is dimensionless:

,

which is dimensionless:

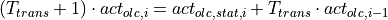

The continuous form can therefore be transformed to match the discrete form above:

A comparison of coefficients between the two transfer functions result in the

following equations for the factors  and

and  :

:

The behaviour is parameterized through  to make it independent

from the simulation step size. For normal situations,

to make it independent

from the simulation step size. For normal situations,  is set to

0.12 s. If the controller detects a major brake manoeuvre,

is set to

0.12 s. If the controller detects a major brake manoeuvre,  is set

to 0.08 s. A major brake manoeuvre is declared by a desired brake pedal position

greater or equal to 60 % of the maximum possible pedal actuation way.

The calculations above are done in the function ApplyFirstOrderTransientBehaviour

of the sub-module ALongitudinalDataProvider. It is applied to the

inverted longitudinal dynamics model

in the function ControllerPedalPosition of AlgorithmLongitudinalDriver.

is set

to 0.08 s. A major brake manoeuvre is declared by a desired brake pedal position

greater or equal to 60 % of the maximum possible pedal actuation way.

The calculations above are done in the function ApplyFirstOrderTransientBehaviour

of the sub-module ALongitudinalDataProvider. It is applied to the

inverted longitudinal dynamics model

in the function ControllerPedalPosition of AlgorithmLongitudinalDriver.

Compensatory control on stabilization level

The velocity controller is designed as a simple proportional controller. The

general transfer function of a P-controller with the input signal velocity error

and the output signal pedal position

and the output signal pedal position  is described as:

is described as:

The controller amplification  is therefore described as the ratio

between input signal and output signal:

is therefore described as the ratio

between input signal and output signal:

The controller amplification  therefore expresses how many

percent of accelerator or brake pedal position are generated by 1 m/s velocity

error.

therefore expresses how many

percent of accelerator or brake pedal position are generated by 1 m/s velocity

error.  is currently a constant with a value of 0.5 s/m, which

was empirically determined in the Ph.D. thesis of Marcus Mai, Dresden University

of Technology. A dead zone of

is currently a constant with a value of 0.5 s/m, which

was empirically determined in the Ph.D. thesis of Marcus Mai, Dresden University

of Technology. A dead zone of  for

for  is also implemented

within the controller, which has to be exceeded for the controller even doing

anything.

is also implemented

within the controller, which has to be exceeded for the controller even doing

anything.

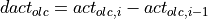

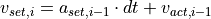

As Fig. 52 illustrates, the calculation of  is done by subtracting

the actual velocity

is done by subtracting

the actual velocity  of the vehicle from the desired velocity

of the vehicle from the desired velocity

by the driver behaviour model, which is the desired acceleration

by the driver behaviour model, which is the desired acceleration

integrated over time:

integrated over time:

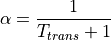

As openPASS is a time discrete simulation platform, integration of values over

time must also be done in incremental steps. In relation to  ,

this means which value the velocity in the current time step i should have,

if

,

this means which value the velocity in the current time step i should have,

if  from the last time step

from the last time step  would have been applied

properly to the actual velocity

would have been applied

properly to the actual velocity  in this last time step,

considering the step size dt:

in this last time step,

considering the step size dt:

The calculations above are done in the function ClosedLoopController of the sub-module ALongitudinalDataProvider. It is applied to the open-loop controller in the function ControllerPedalPosition of AlgorithmLongitudinalDriver.

Application of the pedal change time

The application of the pedal change time is done by the function RegardPedalChange,

which calls further sub-functions. It checks, if a sign change in the controller

output act occurs and counter checks it towards already ongoing pedal changes.

If a pedal change have to be applied, a pedal change time is sampled from a

lognormal distribution, which is defined by a minimum value, a mean value and a

standard distribution. These parameters are received from the module

ParametersAgent. The sampling of a

new value from this distribution is done for each pedal change to consider

intra-individual differences of the driver. Over the next time steps, the time

since the beginning of the pedal change is summed up, until the pedal change

time is met. In this time frame, no actuation of any pedal is possible and the

output values  and

and  are set to zero. After the

completion of the pedal change, the actuations from the controllers are further

processed and split up into the output signals.

are set to zero. After the

completion of the pedal change, the actuations from the controllers are further

processed and split up into the output signals.